Introduction

A leading aerospace supplier sought to optimize the production of composite wastewater tanks for civil aircraft, aiming to reduce costs, labor, and manufacturing time while improving product quality and consistency.

Challenge

The client’s original manufacturing approach was complex, inefficient, and labor-intensive.

Key challenges included:

- Multiple, disjointed production steps requiring manual intervention

- High material usage and long lead times

- Error-prone processes that increased rework and costs

Specifically, the tank shell was wound and cured separately, the internal liner was applied manually, and attachments like brackets were glued on in separate steps, each adding time, cost, and variability to the process.

Solution

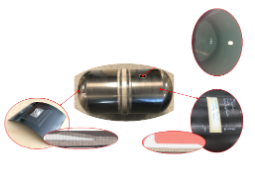

COTESA developed an innovative one-shot manufacturing process, integrating several production steps into a single, efficient workflow:

- External layup tool: Enabled precise placement of attachments directly in the tool

- Co-curing: Shell, liner, and attachments were cured together in an autoclave for cohesive bonding

- Thermoplastic film liner: Replaced manual coating and served as a water barrier with autoclave compatibility

- Automated Fiber Placement (AFP): Improved material usage and allowed optimized fiber placement, especially in dome areas

- 3D printing interface: A ULTEM carrier film was included to support future retrofits or component repair with 3D-printed parts

This replaced a multi-step manual process with a streamlined, high-precision system.

Conclusion

The new one-shot process delivered major improvements:

- Significantly reduced lead times

- Lower material and labor costs

- Improved quality and consistency through automation

- Fewer errors and less rework

- Expanded innovation potential via 3D-printing compatibility

The result was a modernized production line that delivered better performance, at a lower cost, and in less time, setting a new benchmark in wastewater tank manufacturing for the aviation sector.